The world of gemstones is a captivating realm where nature’s wonders and human ingenuity converge. In this exploration, we delve into the intriguing domain of synthetic sapphires – the jewels that have captured the imagination of gem enthusiasts and jewelry connoisseurs alike.

The Essence of Sapphire

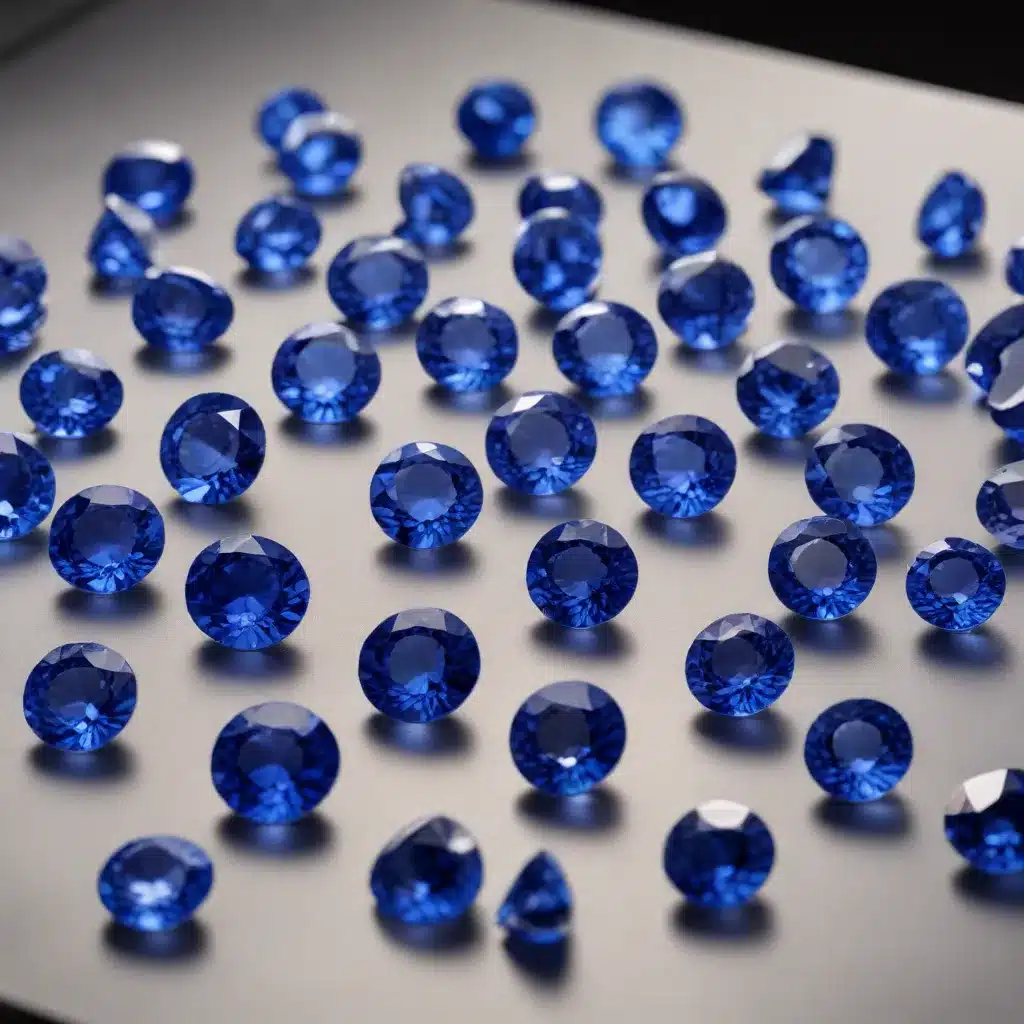

Sapphires, revered for their timeless beauty and unparalleled durability, have long been a symbol of royalty, wisdom, and spiritual enlightenment. These exceptional gemstones are renowned for their crystalline structure, which is composed of the mineral corundum, a naturally occurring aluminum oxide. The presence of trace elements, such as iron and titanium, within the corundum matrix is what gives sapphires their diverse and mesmerizing range of colors, from the deep, velvety blues to the elusive and sought-after pink, yellow, and purple hues.

Sapphire Composition and Structure

At the heart of a sapphire’s allure lies its atomic structure, which is characterized by a highly organized and symmetrical arrangement of aluminum and oxygen atoms. This intricate crystalline architecture not only contributes to the gem’s exceptional hardness (9 on the Mohs scale) but also imparts its remarkable optical properties, including high refractive index and dispersion, which are responsible for the gem’s captivating sparkle and brilliance.

Optical Properties of Sapphire

The exceptional light-handling capabilities of sapphires are a key factor in their desirability. The high refractive index of these gemstones, combined with their double-refracting nature, creates a dazzling interplay of light, resulting in the iconic “fire” and “scintillation” that make sapphires so mesmerizing. Additionally, the dichroic nature of sapphires, which allows them to display different colors when viewed from different angles, adds to their enchanting and multifaceted appeal.

Synthetic Sapphire Applications

The unique properties of sapphires have made them valuable not only in the realm of jewelry but also in various industrial and technological applications. Synthetic sapphires, in particular, have found widespread use in applications such as watch crystals, laser components, semiconductor substrates, and even specialized optics, where their exceptional hardness, transparency, and thermal conductivity make them indispensable.

The Synthetic Sapphire Industry

The pursuit of creating synthetic sapphires has been a captivating endeavor, driven by both the desire to replicate nature’s masterpieces and the practical need for high-performance materials in modern technologies.

Market Trends and Demand

The growing demand for synthetic sapphires has been fueled by several factors, including the rising awareness of the environmental and ethical concerns associated with the mining of natural gemstones. Furthermore, the consistent quality, affordability, and availability of synthetic sapphires have made them an increasingly attractive option for jewelry enthusiasts, designers, and industries seeking reliable, conflict-free materials.

Technological Advancements

The art of synthetic sapphire production has undergone remarkable advancements in recent decades, enabled by the development of sophisticated crystal growth techniques and the deployment of cutting-edge manufacturing technologies. These innovations have allowed for the creation of synthetic sapphires that are virtually indistinguishable from their natural counterparts, both in terms of physical properties and visual appearance.

Manufacturing Processes

The two primary methods used in the production of synthetic sapphires are the Czochralski process and the flux method. The Czochralski process involves the controlled growth of a single crystal from a melt, while the flux method utilizes a solvent-based approach to encourage the growth of synthetic sapphire crystals. Both techniques are carefully orchestrated to ensure the production of high-purity, defect-free sapphire crystals that can be subsequently cut, polished, and refined into the dazzling gemstones that adorn jewelry and serve industrial applications.

Quality Assurance in Synthetic Sapphire

Maintaining the impeccable quality of synthetic sapphires is a crucial aspect of the industry, ensuring that these engineered gems meet the exacting standards demanded by both consumers and specialized applications.

Purity and Clarity Evaluation

The production of synthetic sapphires involves meticulous control over the growth environment, chemical composition, and processing parameters to achieve exceptional purity and clarity. Advanced analytical techniques, such as X-ray diffraction and spectroscopic analysis, are employed to verify the chemical composition and crystal structure of the synthetic sapphires, ensuring they are identical to their natural counterparts.

Color Grading and Uniformity

The vivid and uniform colors of synthetic sapphires are a testament to the precision of the manufacturing process. Color grading systems, similar to those used for natural gemstones, are applied to evaluate the hue, saturation, and tone of synthetic sapphires, guaranteeing consistent and captivating color profiles across the product line.

Certification and Standardization

To further instill confidence in the quality and authenticity of synthetic sapphires, the industry has adopted certification and standardization practices. These measures, often facilitated by respected gemological laboratories and industry associations, provide independent verification of the origin, characteristics, and provenance of synthetic sapphires, ensuring transparency and building trust among consumers and jewelry professionals.

Sustainability in Synthetic Sapphire Production

As the awareness of environmental and social responsibility grows, the synthetic sapphire industry has embraced a commitment to sustainability, actively addressing the challenges and opportunities inherent in this evolving landscape.

Environmental Impact Mitigation

The production of synthetic sapphires, in contrast to the potentially disruptive effects of traditional mining, offers a more sustainable approach. Manufacturers have implemented energy-efficient technologies, water-reclamation systems, and waste-management strategies to minimize the environmental footprint of their operations, aligning with the broader shift towards green and responsible gem sourcing.

Energy-Efficient Manufacturing

Synthetic sapphire production relies on high-temperature processes, which can be energy-intensive. However, industry leaders have spearheaded the adoption of renewable energy sources, advanced furnace designs, and process optimizations to reduce the overall energy consumption and carbon footprint associated with synthetic sapphire manufacturing.

Waste Management Strategies

The responsible handling and disposal of byproducts and waste materials generated during synthetic sapphire production are essential for preserving the delicate balance of the environment. Manufacturers have implemented comprehensive recycling programs, closed-loop systems, and innovative waste-to-value initiatives to ensure that the production of these engineered gems aligns with the principles of a circular economy.

The world of synthetic sapphires is a testament to human ingenuity, where the pursuit of perfection and the respect for sustainability converge. As the industry continues to evolve, the Shelby Gem Factory remains at the forefront, crafting these captivating gemstones with unwavering commitment to quality, innovation, and environmental stewardship. Discover the allure of synthetic sapphires and explore the Shelby Gem Factory’s collection to uncover the brilliance that awaits.